Technical parameter

|

Device model |

VLT-1000B |

VLT-1200B |

VLT-1400B |

VLT-1500B |

VLT-1600B |

VLT-1800B |

VLT-2000B |

|

Size |

1000×1500 |

1200×1650 |

1400×1800 |

1500×1850 |

1600×1950 |

1800×1950 |

2000×2100 |

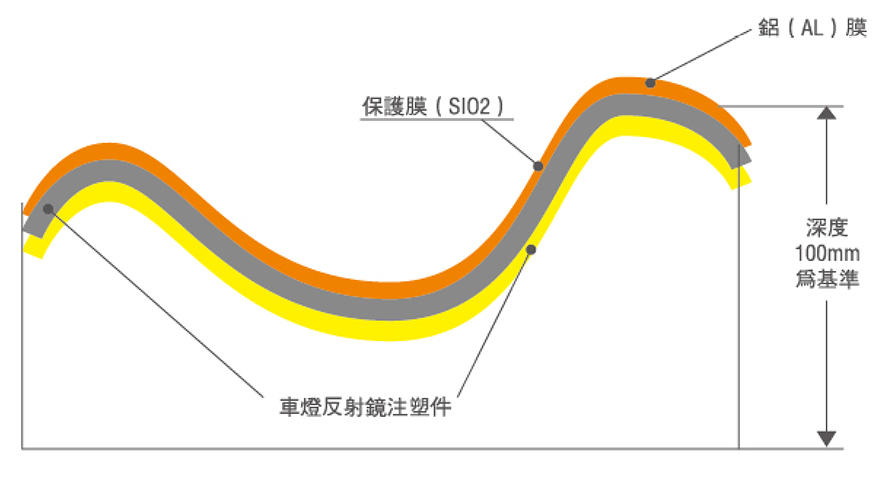

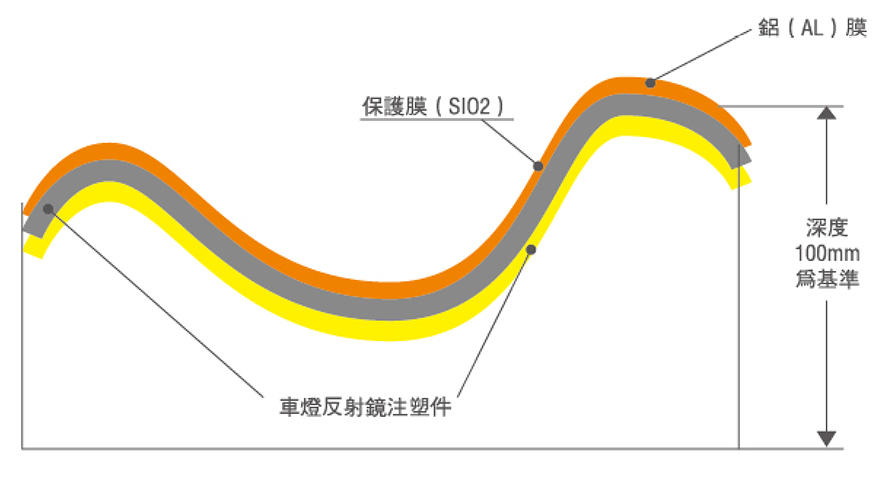

Type of film: auto lamp reflective aluminum film automatically completes the coating and protective film overlap process at one time

Power supply type: double door, air extraction system

Vacuum system: slide valve pump + roots pump + diffusion pump + maintenance pump (or optional: cryogenic pump, cryogenic system)

Protective film monomer: independent stainless steel gas tank

Inflation system: mass flow controller control

High pressure bombardment system: 13KVA 3000v

Ultimate vacuum: 6×10-4pa (no load, clean room)

Pumping time: no-load air pumping to 5×10-2pa less than or equal to 6 minutes

Workpiece rotation: single axis/6 axis/8 axis revolution and rotation/dual frequency stepless speed regulation

Control method: manual + semi-automatic + fully automatic integration / touch screen + PLC

Remarks: The size of the vacuum chamber can be customized according to customer's product and special process requirements

Equipment characteristics

The same period of production: -900sec/(15 minutes) shorter than the same period of production for similar equipment

Coating method: heating system evaporation coating and protective coating are completed at the same time (no other anti-gasification treatment is required after coating)

Coating quality: Each door has 6-8 sets of fixtures for both rotation and revolution. The coating thickness is uniform, which is suitable for mass production of economical car lights.

Dehumidification capacity: the vacuum chamber is equipped with an ultra-low temperature refrigeration system below minus 140 degrees, which fully absorbs moisture to increase the vacuum reach speed

Operating cost: The volume of the vacuum chamber is relatively large, the number of coatings is large each time, and the operating cost of a single piece is low

Number of fixtures: According to the size of the product, the fixture can be changed to 6 axis or 8 axis at will, without any installation and adjustment when changing

Defective product rate: omit the usual processing procedures (primer coating and aluminum film protective paint spraying) to reduce defective products

Floor area: double-door structure, relatively smaller installation area and operation area than similar equipment

Operation method: The man-machine interface can be set and monitored intuitively, and the person who has no management password can not change it

After-sales service: There is an after-sales service center and parts warehouse, which can quickly deal with problems in use

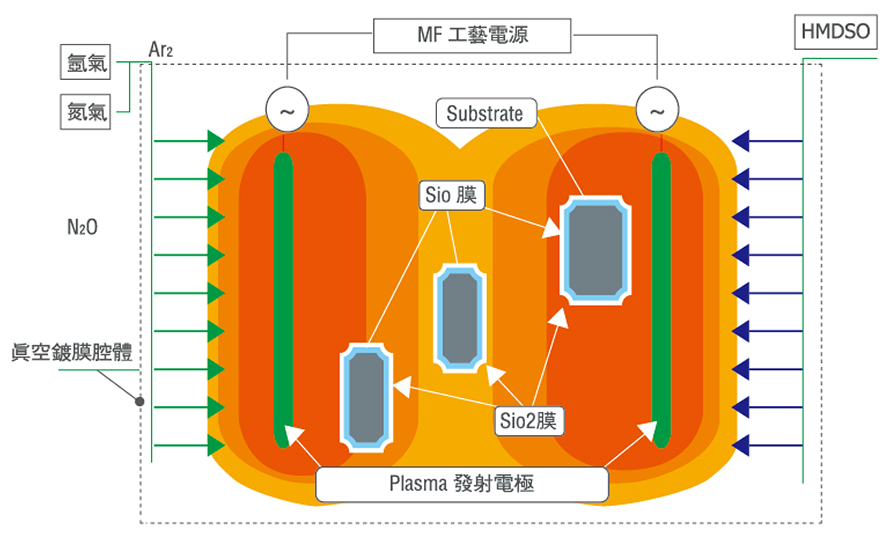

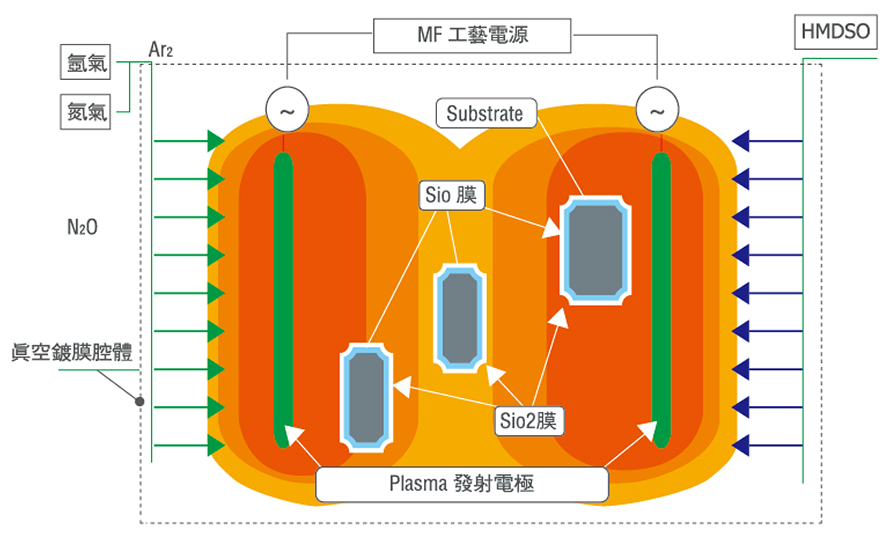

Equipment principle

In a suitable vacuum environment, the heating wire is supplied with a certain voltage, so that the aluminum wire placed on the heating wire evaporates on the surface of the rotating product to achieve the purpose of aluminum plating. The HMDSD (paint) and Nitrous (N20)

Under the high voltage of several hundred volts, it reacts into silicon gel (Si02), and adheres to the metal film plated in the previous process to prevent oxidation.

Schematic diagram of protective coating

Clean the surface of the injection molded object by generating an electric arc at an intermediate frequency

Activation to improve the adhesion of coated articles

Fully exhaust in a high vacuum environment

Metal coating through DC power supply

Protective film coating through intermediate frequency power supply

Carry out the hardening of the protective film

產(chǎn)品鍍膜原理圖

PERSONMr. Cheng

PERSONMr. Cheng TEL0510-88769360?

TEL0510-88769360?  FAX0510-88769196

FAX0510-88769196 WEBwww.cntmw.com

WEBwww.cntmw.com E-MAILCL@jsvltvac.com

E-MAILCL@jsvltvac.com ADDNo. 11, Nongke Team Road,

ADDNo. 11, Nongke Team Road,